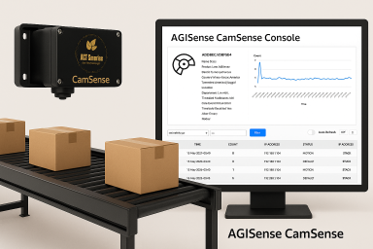

AGI CamSense

An advanced wireless camera-based sensor system engineered for real-time monitoring of goods on conveyor belts—making it an ideal solution for industrial automation and logistics. It offers precise item counting, anomaly detection, and immediate alerting for irregularities, supporting proactive maintenance and operational safety. Its compact, wireless design allows for easy installation and seamless integration into existing workflows. CamSense helps businesses boost efficiency, ensure accuracy, and maintain continuous visibility of operations on the move.

AGI CamSense Functionalities

Key Features

Real-Time Box Counting : Uses photoelectric sensors to accurately count items on the conveyor.

Height Verification : Laser distance sensors check the height of goods to ensure size consistency.

Connectivity & Integration

Wireless Gateway : Uses LoRa or Wi-Fi to transmit data without physical wiring.

Cloud Dashboard : Enables remote access, real-time insights, and historical data logging.

Edge Compatibility : Supports on-site processing for faster response and reduced latency.

Sensor Capabilities

Photoelectric Sensor : Detects and counts each passing object.

Laser Distance Sensor : Measures item height with precision for quality control.

Applications

Factory Automation : Conveyer line monitoring, Monitor production lines with minimal manual intervention..

Logistics : Track and verify shipments automatically.

Warehousing : Object based counting solutions

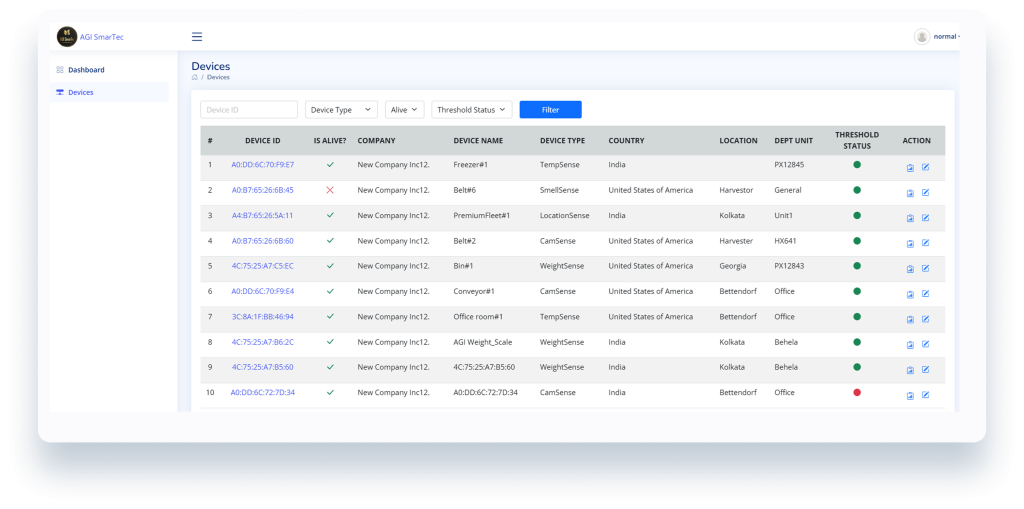

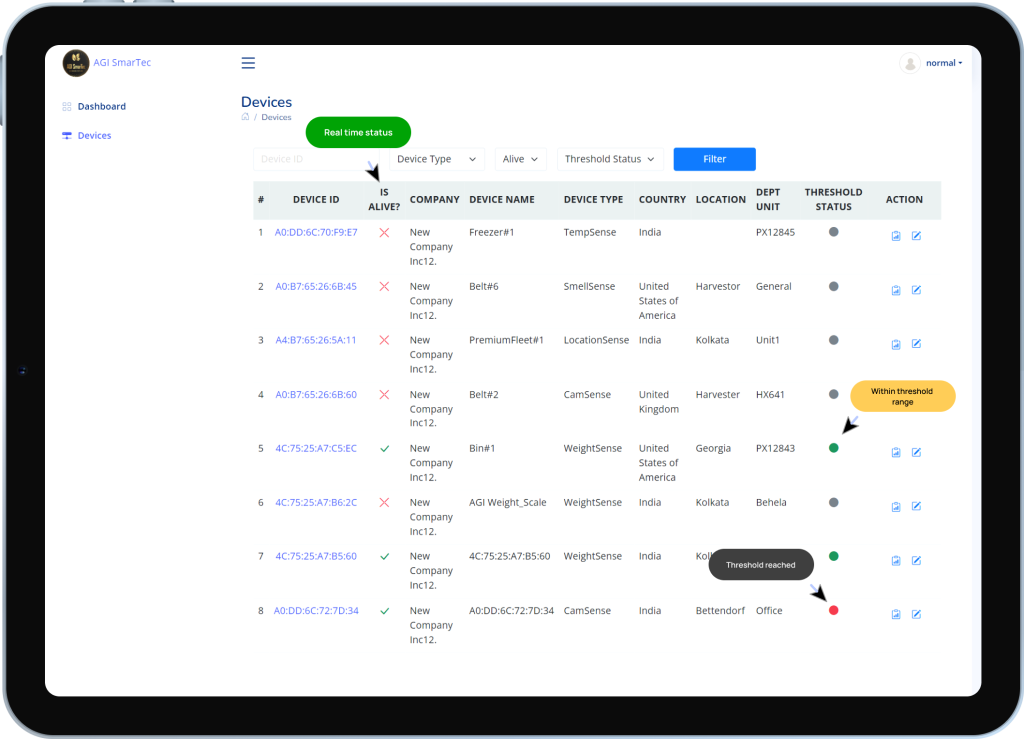

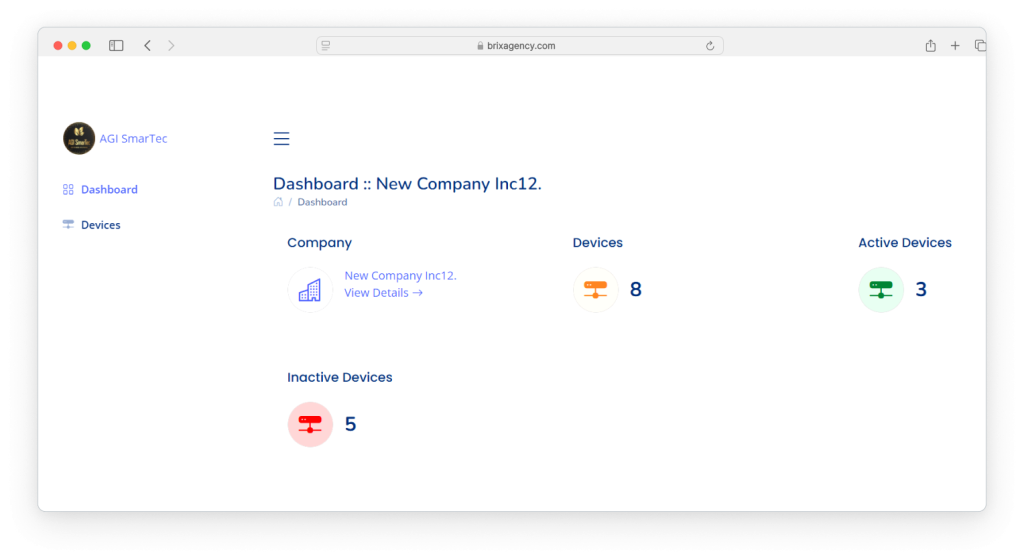

Unlock the Full Power of Your Device

with Our Smart Dashboard

Every AGI device is backed by a powerful, subscription-based dashboard that gives your team the ability to track performance, configure thresholds, and take real-time action — all in one place.

Built for Action. Designed for Simplicity!

Set It Once. Stay Informed Always.

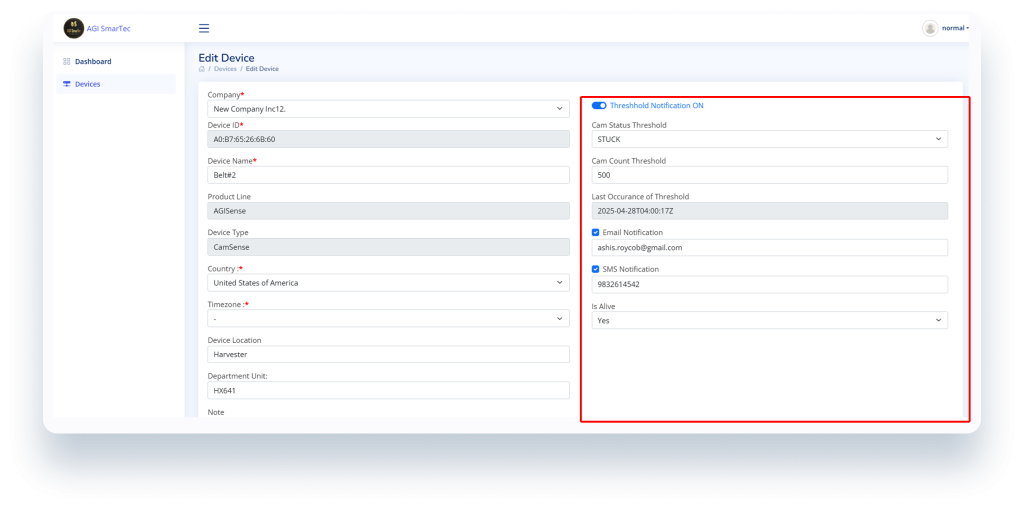

isAlive Status

Each device reports a live “isAlive” status — if no data is received for over 1 hour, the status changes to false, helping your team act fast on device issues or disconnects.

Threshold Status Monitoring

Set and adjust threshold values specific to your use case or environment. Whether you’re tracking temperature, weight, or gas levels — define what matters, and let the system alert you when it matters most.

Edit Device Info (Location Details)

Update and manage device locations directly from the dashboard, making it easier to map your infrastructure and respond to alerts with spatial awareness.

Device Configuration

Precision at Your Fingertips

From defining motion detection rules to specifying regions of interest (ROI), AGI CamSense offers fine-tuned configuration options to help you track, verify, and control your conveyor operations with precision.

Motion Detection Settings

Define when an object should be detected — based on movement speed, duration, or ROI positioning.

Region of Interest (ROI) Setup

Mark zones on the belt to monitor for irregular stops or stuck items.

Object Count & Validation Parameters

Set expected item counts and dimensions — get notified when items deviate from defined specs.

Notification Trigger Logic

Configure conditions for specific alerts (e.g., “Box stuck in ROI for > 5s” triggers a warning).

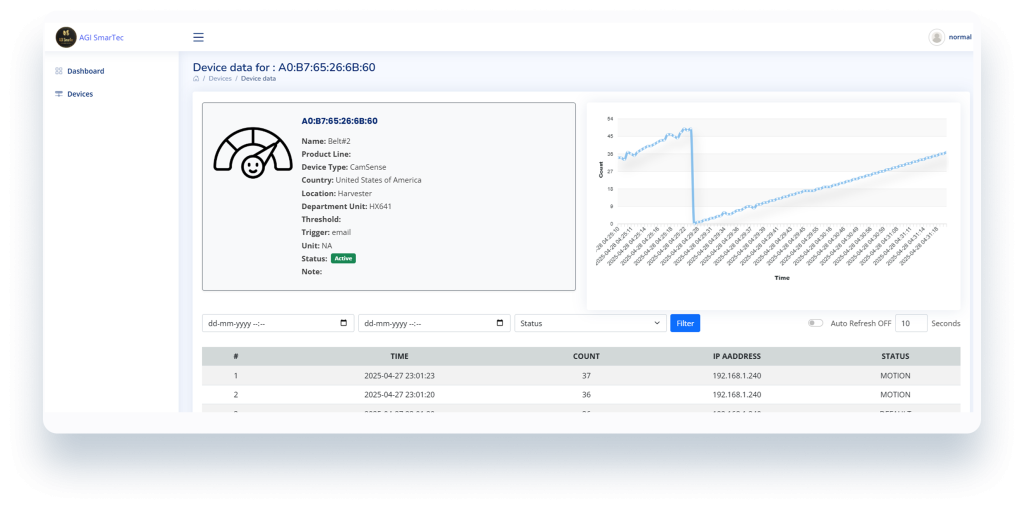

Track Every Object, in real time.

With complete oversight.

AGI CamSense brings industrial monitoring into the modern age. View object flow, count validation, and stuck-item alerts live — all from a sleek dashboard that’s optimized for speed, clarity, and action.

When Every Second Counts —

We Notify Instantly.

AGI Smartec’s alerting engine doesn’t just monitor your environment — it thinks for you. When thresholds are crossed or a device goes silent, our system springs into action, instantly triggering precise alerts through Email and SMS, so you can react in real time and stay ahead of risk.